CRDI vs TDI – Which One Is More Superior and Reliable?

Common Rail Direct Injection is abbreviated as CRDI, whereas Turbocharged Direct Injection is abbreviated as TDI. These two engine technologies are ideal for passenger cars as well as trucks. Additionally, they can be used with your diesel engines. This article will discuss the distinction between CRDI and TDI.

CRDI vs TDI

CRDI is a technology that reduces the quantity of fuel wasted in the new system of diesel engines. CRDI has been demonstrated to be fuel-efficient and improve the machine’s performance, just like any other diesel technology [1].

Since the fuel inside the common rail is set at a predetermined pressure level, it breaks down the fuel to its smallest particles. As a result, gasoline and air can combine more effectively using this strategy.

Some studies claim that CRDI has given diesel engines a 25% performance boost [2].

This is because the CRDI controls the amount of fuel to be released, the timing of injection, the charge, and the pressure inside the common rails.

Although CRDI is slightly more expensive than other diesel engine technologies, less fuel is wasted, which can result in significant fuel cost savings.

The term “turbocharged direct injection,” or “TDI,” refers to a turbocharged and direct-injected cylinder turbo diesel engine. The well-known Volkswagen Group in Europe created TDI. The cars compatible with TDI have been carefully chosen, particularly those made by Volkswagen.

Volkswagen’s TDI is compatible with its light commercial vehicles, marine engines, and passenger cars. More air can enter the cylinders thanks to the turbocharger in TDI vehicles.

Additionally, the temperature is lower, allowing greater fuel injection and combustion capacity [3]. Due to its modest surface area, the TDI increases engine efficiency with less audible combustion noise.

Difference between TDI and CRDI

TDI (Turbocharged Direct-Injected)

Direct fuel injection and turbocharging are combined in the TDI system. The fuel injector injects gasoline into the engine, which is then sprayed into the combustion chamber. Direct injection generates fuel atoms, which are then delivered to the combustion chamber [4].

When the engine burns fuel or conducts combustion, the system and turbocharger increase the air volume. It facilitates enhanced combustion.

The TDI’s intercooler aids in cooling the engine. As a result, the fuel infusion for combustion can be increased. In addition, the TDI engine is more effective since there are fewer heat losses due to the less open surface area. The technology is present in most vehicles made by the Volkswagen group.

They use it in commercial vehicles and ship engines. Utilizing this technology results in significant power and improved efficiency.

CRDI (Common Rail Direct Injection)

With bearable emissions, the CRDi diesel engine emits much less smoke. They also have better fuel efficiency because they use a common rail to transport fuel. Therefore, they no longer consume a lot of gas.

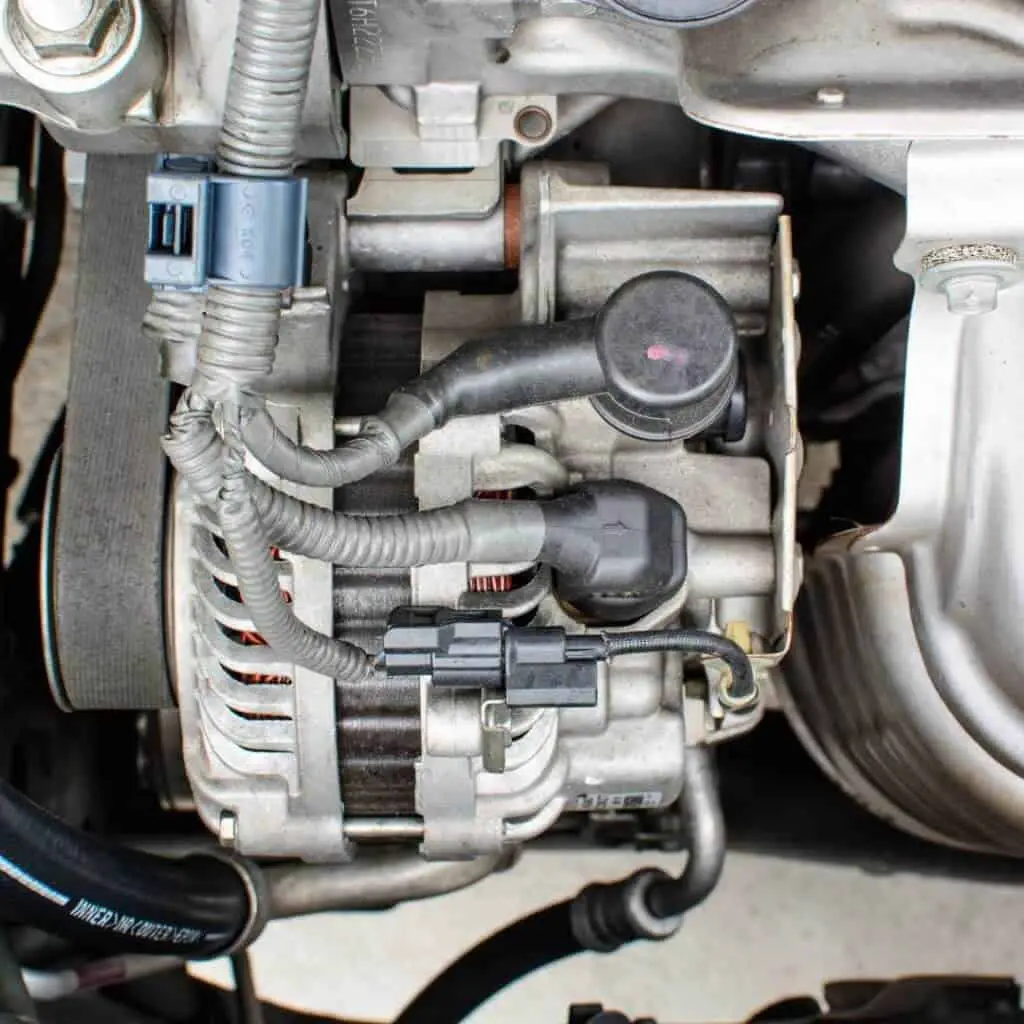

They outperform gasoline engines in terms of fuel economy since they get better mileage. Fuel is injected into the engine cylinders of petrol and diesel engines using a technology called common rail direct injection, or CRDI. A high-pressure common rail injects the fuel into individual engine valves.

Most modern generation engines adopt this system because of technological advancement. Therefore, the system’s fuel injectors are all connected to the same pipe. This common line is known as the “common rail.”

Robert Huber created the first version of the CRDI [5]. He developed the prototype in the 1960s. A few other people who helped progress this technique came after him. After Robert Huber, Dr. Marco Ganser carried on working on it. In the 1990s, this method was used in the Japanese automobile industry.

Instead of using traditional injectors, sophisticated solenoid injectors will be utilized [6]. The fuel is distributed uniformly to all cylinders in this arrangement using a single fuel distribution pipe. Because of this, the system is known as the common rail system. The gasoline can be kept here, and it also aids in maintaining pressure.

Solenoid injectors receive consistent supply and storage thanks to the common rail. Injectors and a turbocharger are combined in the modern engine with CRDI to boost efficiency. It enhances power production and lowers emissions.

Advantages of the CRDI system

Modern diesel engines use a technique of fuel injection called the common rail. Common rail systems offer adaptability that can be used for best-in-class fuel, power, and pollution control.

Because of this, Original Equipment Manufacturers (OEMs) can create a wide range of equipment and applications for the best performance and outstanding end-user value.

Modern diesel engines frequently employ common rail direct injection systems because of their adaptability and capacity to meet the tightest environmental standards.

In common rail systems, the gasoline is precisely and under pressure delivered to the engine by electronic control. This offers versatility that can be used to achieve class-leading levels of power, fuel, and pollution control.

The programmable control module used by CRDi ensures that the fuel injection timing, the amount of fuel, and the atomization or fuel spray are all electronically controlled [7]. With respect to predetermined parameters, this permits numerous injections at any pressure at any time, offering flexibility that can be used to improve power, fuel efficiency, and pollution control.

Among the benefits of the CRDI system are the following:

- Lower Emissions: CRDi diesel engines were created due to demand. Older diesel engines frequently produced smoke that looked like black soot and had terrible emissions. The smoke and pollution from the CRDi diesel engine are bearable.

- Better Fuel Economy: Because CRDi engines use a common rail to transfer fuel, they no longer consume a lot of gas. They outperform gasoline engines in terms of fuel efficiency because of their high mileage.

- Lessened Engine NVH: Due to the development of diesel engine technology, which has fewer moving parts. Quieter engines include CRDI.

- Enhanced Power: CRDI engines have tremendous power. A CRDi diesel engine can provide up to 25% greater torque than a petrol engine using the same quantity of fuel.

Hyundai CRDI engine

An example of a diesel engine using a common rail direct injection technology is the Hyundai CRDi engine. According to this technology, each cylinder’s combustion chamber receives a direct injection of diesel fuel, as opposed to the air intake manifold used by most diesel engines.

As a result, better fuel efficiency is achieved due to the combustion process being made more efficient. Additionally, compared to conventional diesel engines, the engine is quieter and emits fewer pollutants.

For instance, the R 2.0 Litre CRDi diesel engine can produce 400 NM of maximum torque at 1750 to 2750 rpm and 185 PS of pure power at 4000 RPM [8]. On board the Hyundai Tucson, the high power/high torque engine is standard.

CRDI cars

As modern automobile technology enriches human lives all over the globe, little is known about what’s doing under the car’s hood! It is comparatively easy to get lost in those abbreviating terminologies.

Ever wondered what the CRDi stood for in your new diesel fuel-driven car? Hyundai and Kia automobiles have turbocharged CRDI engines as standard equipment.

The engine of a CRDI vehicle sounds quieter and more pleasant. The operation is also more fluid. Because increased injection pressure results in a finer fuel spray (atomization) that burns more effectively, you will also experience gains in fuel usage. The key to fulfilling emission standards is improved combustion efficiency.

Toyota Innova, Hyundai vehicles like the Intrado, Maruti Swift, and Tata vehicles’ SUV lineup are well-known brands in the Indian auto industry for their CRDI engine automobile technology.

Injection systems for diesel engines and compression ignition come in two main varieties (CRDI Engines). Two examples are the air injection system and the airless or solid injection system.

Read Also: Glow Plug Light Flashing VW

Conclusion

In order to increase economy, the TDI incorporates a turbocharger for exhaust gas recirculation. TDI diesel engines are exclusively available in cars and car brands controlled by Volkswagen, and they are more expensive but simpler and generally less expensive to maintain.

For effective fuel delivery, CRDi utilizes a high-pressure fuel injection system. Although CRDi is more sophisticated and, therefore, more costly to operate and maintain, it is less expensive to manufacture and may be utilized for a variety of automobiles and car brands.